DESCRIPTION: Advantage 3 Programmers / Controller

Contains the necessary parts and instructions required for upgrading any make or model of heat treatment unit to provide the additional functionality, user benefits and cost savings provided by the ‘Advantage 3’ linkable programmer/controller.

Industry Standard for Heat Treating Industry.

Advantages:

1) Cost Savings

2) Versatilty

3) Time Savings

4) Flexibility

5) Ships to the USA & Canada

Can be used individually or combined to control temperature differntials in a number of configurations.

This control temperature is very important in the following test;

a) ASME, b) BS, c) EN, d) ANSI, d) DIN.

The advantage three is fitted for the standard Cooperheat unit six channel Heat treament console.

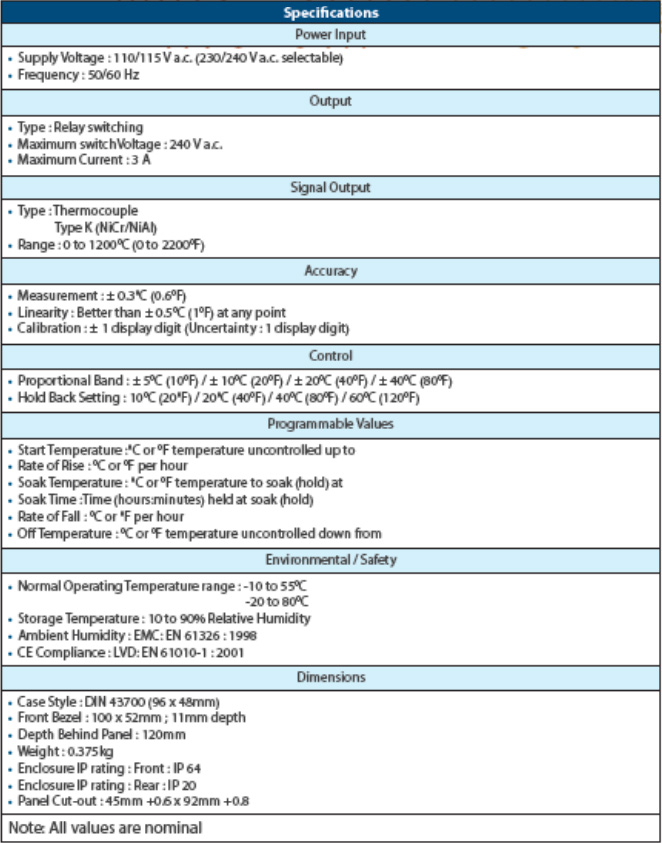

See ‘Advantage 3 upgrade kit’ technical specification for full details.

Stock reference & description:

12300 – ‘Advantage 3’ linkable programmer/controller, heat treatment unit upgrade kit

Replacement ‘Advantage 3’ linkable, programmer/ controller. See ‘Advantage 3’ data sheet for full details and technical specification.

Stock reference & description:

548-055 – ‘Advantage 3’ linkable, programmer/controller

BENEFITS : ADVANTAGE THREE CONTROLLER / PROGRAMMER

> USER FRIENDLY OPERATION AND CALIBRATION

> CLEAR , ILLUMINATED DISPLAY SHOWING ACTUAL AND SET TEMPERATURES

> PLUG IN CONNECTIONS ENABLE REPLACEMENTS IN SECONDS

> EASY TO PROGRAM , OPERATE AND INTERROGATE

> COMPLIES WITH EUROPEAN LVD AND EMC DIRECTIVES AND CE MARKED

> OPERATE AND DISPLAY IN C AND F WITH SIMPLE SELCTION

> DISPLAY BOTH SET POINT TEMPERATURE AND ACTUAL WORK PIECE TEMPERATURE

> USER CONTROLLED OPTIONS TO CHNGES PROPORTIONAL BAND AND HOLD BACK POINT

> UNIIQUE LINKABLE FEATURES THAT ALLOW THE OPERATOR TO ARRY OUT UP TO SIX HEAT

> TREATMENT CYCLES SIMULTANEOUSLY , WHILST CONTROLLING TEMPERATURE CONTRO, ZONE DIFFERENTIALS AS REQUIRED BY INTERNATIONAL HEAT TREATMENT CODES AND STANDARDS