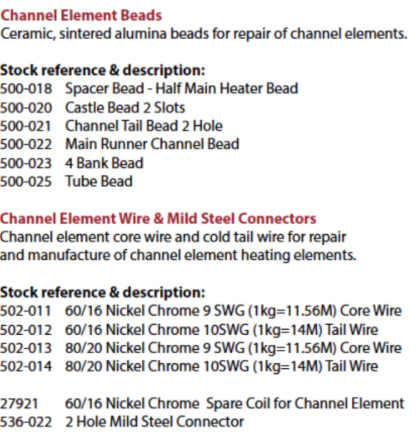

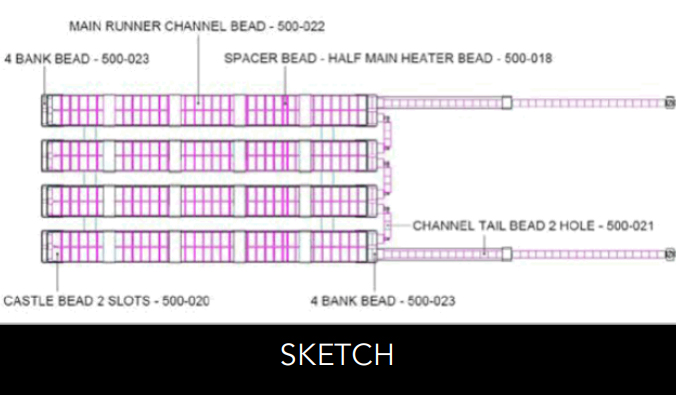

CHANNEL BEADS

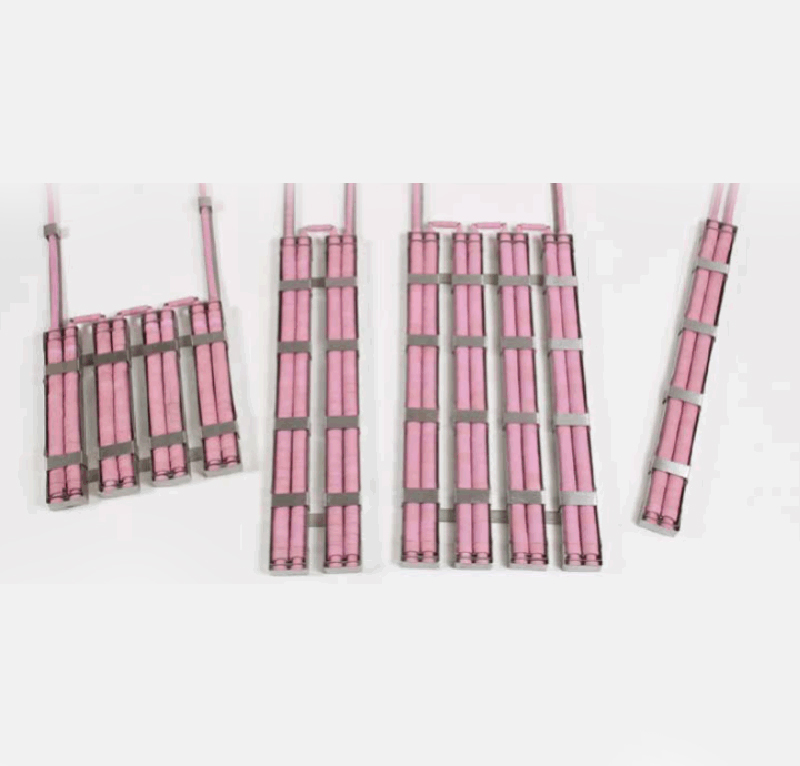

MULTIBANK CHANNEL HEATERS

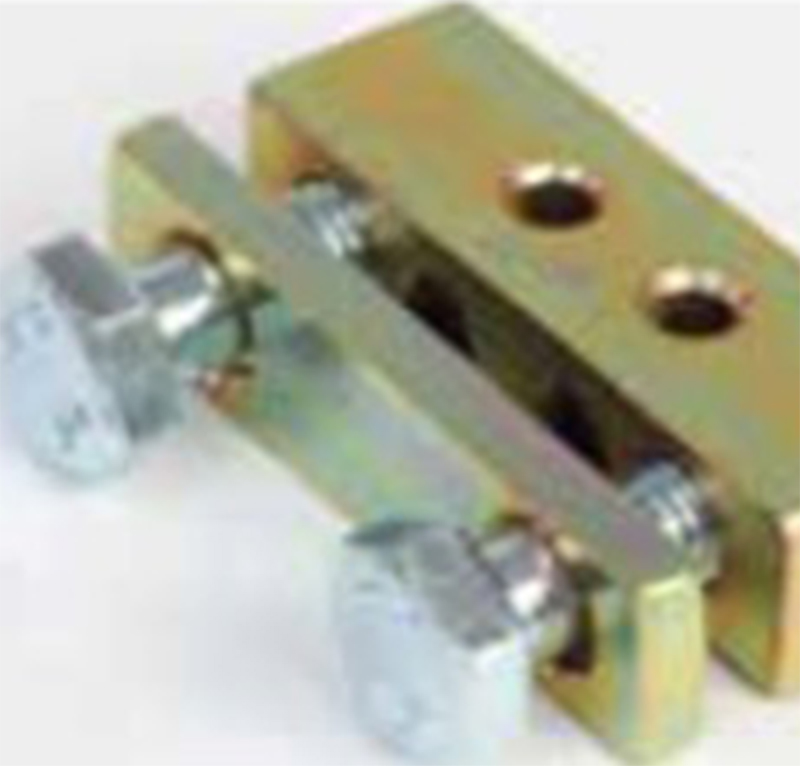

STEEL CONNECTOR

CHANNEL COIL

CHANNEL HEATER

Application for post weld treatment (PWHT) of large welded constructions.

This includes heat treatment Steam drums, vessels and furnaces that use Channel bank heaters for industrial heat treatment.

In addition Multi channel bank heaters are very affected in repairing mining equipment Like mining diggers.

Most common Channel bank heaters are four bank channel elements. The voltage is 60 and 80 volts that work well with 50 Kva or 70 Kva consoles.

CHANNEL HEATING ELEMENTS: FOUR BANK, DOUBLE AND SINGLE CHANNEL

DESCRIPTION : CHANNEL BANK HEATERS

WHY USE CHANNEL FLEXIABLE CERAMIC HEATERS.

For internal space heating, specialized heating rigs and temporary furnaces.

The channel element can be used to preheat and post heat large welded fabrications including steel drums and pressure vessels, they can also be used as a heat source in temporary furnace installations where multiple heat treatments need to be carried out.

Working temperatures of up to 750C can be achieved, the heaters are capable of higher temperatures using Kanthal core wire. Col tails are welded not crimped for durability and safe working. Strongly constructed of high grade materials the channel element is designed to withstand a long on site working life and in addition has the following features: portable, designed for extended periods of operation, suitable for a wide range of heat treatment applications, selection of sizes, can be used for temporary furnace applications for large fabrications.

A coiled element manufactured from solid drawn 9 swg ICA 135 Or Ni/Cr core wire and insulated with 95 % sintered alumina beads, is supported in a stainless steel tray.

The supply voltages for single channels are 30V, 60V or 80 V and range of multi-bank elements can be made up from single elements or connected either in series or parrell. These elements are powered directly from the incoming 380V or 415 V 3 Phase supply, Channel elements can also be supplied utilising 60V or 80 V supplies which can be powered and controlled via standard 60 V and 80 V output, 50 Kva or 70 Kva heat treatment machines.

APPLICATION INFORMATION:

APPLICATION # 1: HEAT TREATMENT OF FURNACES – WITH MULTI CHANNEL BANK HEATERS

APPLICATION # 2: HEAT TREATMENT OF BULK HEADS – WITH MULTI CHANNEL BANK HEATERS

APPLICATION # 3: MINING EQUIPMENT REPAIR WITH HEAT TREATMENT

WHAT IS THE PROBLEM?

WHAT IS THE SOLUTION?

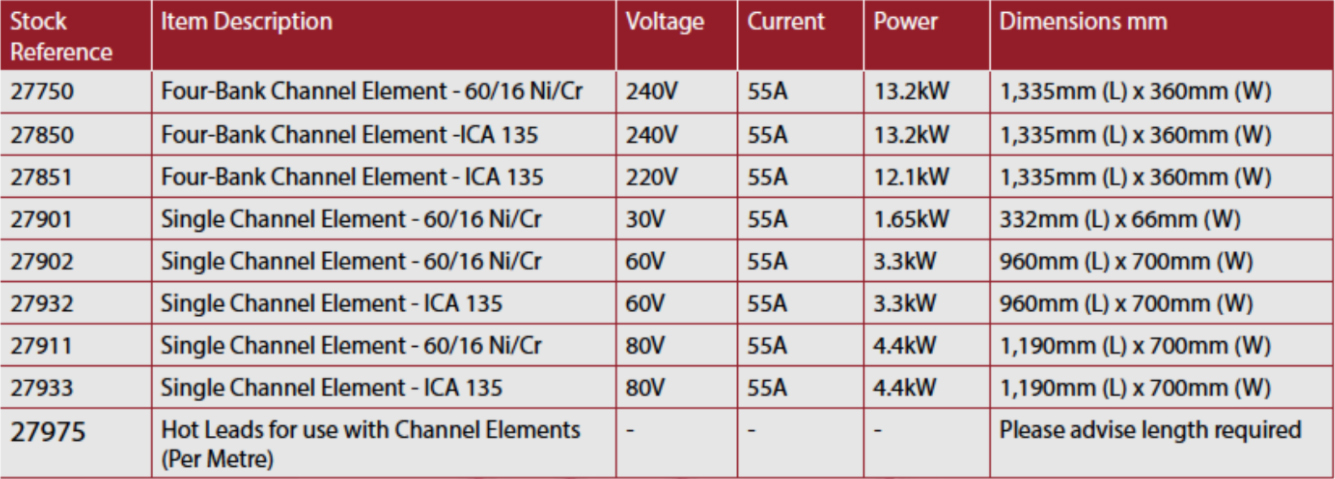

PRODUCT CATALOG NUMBERS:

PRODUCT – PARTS LIST