Infrared Gas Burners

SCU – Surface Combustion Burner

Catalog # 6262/P/3

Shipping to USA & Canada

Introduction

When electrical resistance heating is not possible or too extensive but optimum heat distribution at lowest emission is required you can use Infrared gas burners in use.

Infra-red surface combustion preheater unit’s( SCU’s) are efficient and economical to use.Being simple to set up and versatile in use,they are also suitable for applications other than preheating.

Surface Combustion Unit(SCU)

APPLICATION

1) Preheat vertical or horizontal seams,

2) Circumferential seams on large rotating vessels all to temperatures up to 300C.

3) Natural gas,butane or propane gas(LPG) can be used.

4) Deliverable with flame control and rapid shut-down which responds if burner extinguishes

Specification:

Power: 4.2-8.1 kW

Gas pressure: 0.4-.69 bar or 5.8 – 10.0 PSI

Natural Gas: 1.38 bar or 20 PSI

Consumption: 0.350-0.650 kg/h

Weight: 2.2 kg or 4.4 lbs

Dimensions: 610 mm” x 152 mm (24″ X 6″)

Temp. Operation: 800 C – 1000C

Gas pressure: 0.4-.69 bar or 5.8 – 10.0 PSI

Natural Gas: 1.38 bar or 20 PSI

Consumption: 0.350-0.650 kg/h

Weight: 2.2 kg or 4.4 lbs

Dimensions: 610 mm” x 152 mm (24″ X 6″)

Temp. Operation: 800 C – 1000C

SPECIFICATION

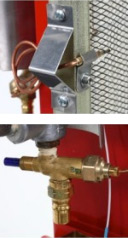

Cooperheat SCU’s operate at surface temperatures between 800C and 1000C.LPG at a pressure of 1.38 bar or natural at a pressure range of between 0.4 and 0.69 bar is fed into the unit,mixed with air in an integral plenum chamber and burned on the external surface of the ceramic fiber face, providing a highly efficient heat source. Burners may be fed singly from a hand controlled manifold,or from Cooperheat’s gasmatic twin heat module control unit (6263/7)providing up to sixteen burners in multiples of four.Ignition can be achieved by lighted taper,paper spill piezo electric ignition which can be supplied as an option.

USER BENEFITS

Gas cost savings of up to thirty-three per cent against the open flame gas burner method of preheating can be achieved by using Cooperheat’s SCU’s,together with more even heat distribution and accurate temperature control

Additional advantages are:

1) Clean and easy to operate

2) Incandescent ceramic fiber tiles give a no flame impingement preheat to the workpiece.

3) Up to three extra burners can be added to a single burner using quick connection couplings

4) Optical pyrometer and roller or skid thermocouples can be provided for temperature control of revolving scen

4) Optical pyrometer and roller or skid thermocouples can be provided for temperature control of revolving scen