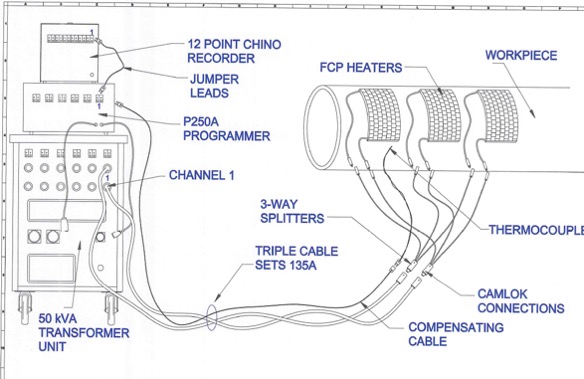

Compliance with international heat treatment codes and standards requires equipment that can provide accurate control of the heat treatment specification parameters, including uniformity of temperature throughout the geometry of the work piece.

Stork Cooperheat’s

- 50kVA – 16050

- 70kVA – 16051

Shipping to USA & Canada

Heat Treatment Modules include our unique ‘Advantage 3’ temperature programmer/controllers which ensure the required temperature uniformity within each control zone. The design of our equipment is based on over 50 years experience as a market leader in the field of heat treatment and has been developed to meet the real needs of the heat treatment engineering industry.

ENGINEERING AND DESIGN

- Value for Money

- Versatility

- Ease of operation and maintenance

- Safety

- Fitness for purpose

16050 and 16051

Advantage Three

STOCK REF # 12300

FEATURES: 16050 AND 16051

- Outputs per channel for both 30V or 60V heaters (40V and 80V output units also available)

- ‘Advantage 3’ operates in °C or °F

- Displays set point and work piece temperature

- LED shows ‘power on’ for each output channel

- Connector block provided for simple connectionof primary supply cable

- Constructed from high-grade stainless steel giving excellent protection against corrosion, including marine offshore applications.

- Core winding thermostats provide automatic protection against transformer coil overheating

- Primary over-current protection provided by a three-phase circuit breaker.

SPECIFICATIONS:

TRANSFORMER CORE:

Three phase, forced air cooled, class H, 70kVA

Primary winding connected in Delta

Secondary winding connected in Star

Auxiliary winding: 110V a.c. 3.3kVA single phase

PRIMARY SUPPLY

Primary voltage: 380V, 415V, 440V

Primary current: 106A, 97A, 92A

Frequency: 50/60 Hz

PRIMARY SUPPLY

Primary voltage: 380V, 415V, 440V

Primary current: 106A, 97A, 92A

Frequency: 50/60 Hz

PROTECTION

Three phase 125A circuit breaker with shunt trip

Three primary core winding over temperature thermostats linked to circuit breaker shunt trip

SECONDARY OUTPUTS

Output: 32.5V – 0V – 32.5V (for 30V and 60V heating element operation)

Auxiliary outputs: Two 110V, 10A, 50/60Hz output sockets

Number of temperature controlled output channels:6 channels

Maximum load per output channel: 10.8kW (e.g. four 60V, 2.7kW heating elements)

Maximum current per output channel: 180A

SWITCHING

Six double pole, 180A, contractors with 110V a.c. coil

TEMPERATURE CONTROL

Temperature measurement, display and control

Degrees Fahrenheit or Degrees Centigrade

Start temperature

Temperature ramp up and down in degrees per hour

Hold/soak temperature set point and hold/soak time period setting

TEMPERATURE RECORDING

Ambient temperature: Minus 0˚C to 50˚C

Humidity: 20% to 80% RH, non-condensing is required (temperature x humidity < 3200)

Environmental protection: IEC IPSO (front door of panel mounted unit)

Input points: 12 Points

Input thermocouple types: Thermocouple inputs- K,

Reference range: Type K: -200˚C to 1370˚C (-326˚F to 249˚F)

Printing system: Ink jet system, 6 colour

Chart Width: 180mm

Chart Length: Z fold 20m

Chart Speed: 5 to 300mm per hour

CONSTRUCTION

Case: 304 Stainless Steel case fitted with four 150mm nylon wheels

DIMENSIONS

Weight: 355kg

Case Dimensions:

Height: 1545mm

Width: 680mm

CHART – COMPARISION – COOPERHEAT

| 16050 | 16051 |

| 50kVA Module | 70kVA Module |

| Tranformer Core | |

|

|

| Primary Supply | |

|

|

| Protection | |

|

|

| Secondary Outputs | |

|

|

| Construction | |

|

|

| Temperature | |

|

|

| Switching | |

| Six double pole, 180a, contractors with 100V a.c. coil | |

MANNINGS UK

MANNINGS

1) 50kVA – 11000

2) 70kVA – 11100

PRODUCT SPECIFICATIONS

TRANSFORMER CORE

Three Phase, Air Natural, Class ‘H’, 50kV

Primary winding connected in Delta

Secondary winding connected in Star

PRIMARY SUPPLY

Primary voltage: 380V, 415V, 440V

Primary current: 106A, 97A, 92A

Frequency: 50/60 Hz

PROTECTION

Three phase 100A circuit breaker with shunt trip

Three primary core winding over temperature thermostats linked to circuit breaker shunt trip

SECONDARY OUTPUTS

Output: 65V

6 temperature controlled output channels

Max load per output channel: four 60V, 2.7kW heating elements

Maximum current per output channel: 180A

CONTROL

Six 110V Energy Regulators

Six 110V Temperature Controllers

One Multi-pin socket for remote programmer

Mode Selection: Six Auto / Manual switches

Indicators: Six 110V neon channel indicators

MAINS CONNECTION

The units are complete with 4.5m of four core primary cable

SWITCHING

Contactorised – six off 200A, 110V a.c. solenoid contactors

CONSTRUCTION

Case: Robust sheet steel case complete with four 150mm diameter wheels

Lifting Method: Fork lift under base

DIMENSIONS

Weight: 302kg

Case Dimensions:

Height: 1010mm

Width: 675mm

Depth: 725mm

| 11000 | 11100 |

| 50kVA Specifications | 70kVA Specifications |

| Tranformer Core | |

|

|

| Primary Supply | |

|

|

| Protection | |

|

|

| Secondary Outputs | |

|

|

| Control | |

|

|

| Dimensions | |

|

|

| Main Connection | |

| The Units are complete with 4.5m four core primary cable | |

| Switching | |

| Contactorised – six off 200A, 110V a.c. solenoid contractors | |