The Cooperheat Twin Heat module is designed to work: with most welding machines to provide accurate control of pre heat and post weld heat treatment.

The Cooper Twin Heat Module channels and controls the current from your welding machine via heavy duty contactors that are regulated by unique Advantage 3 mini programmers, which accurately control the desired temperature of your heat treatment process via thermocouples that run from the work to the Twin Heat Module.

Shipping to USA & Canada

| Catalog: | 13004 | |

| Quality: | ISO 9001:2000 | |

| Accuracy: | + 0.3 C |

Case Dimensions:

| IMPERIAL | METRIC | |

| Height: | 9.8″ | 25 cm |

| Width: | 10.6″ | 27 cm |

| Depth: | 16.9″ | 43 cm |

| Weight: | 27.5 lbs | 12.5 kg |

Twin Heat Module – Specifications

| General Specs: | Display: 8 segment LED, Temperature set point and actual Input Instrument Supply : 110 V a.c , 5A , 50/60 Hz Maximum input per channel: 180 A , 60 V ( up to our parallell connected 60 V , 2.7 Kw heaters per channel ) |

| Environmental / Safety | Environment: Operating temperature range: -10 to + 55 °C |

| Controllers: | Controlled by two ‘Advantage3’ programmer/controllers Temperature input signal : Thermocouple Type K |

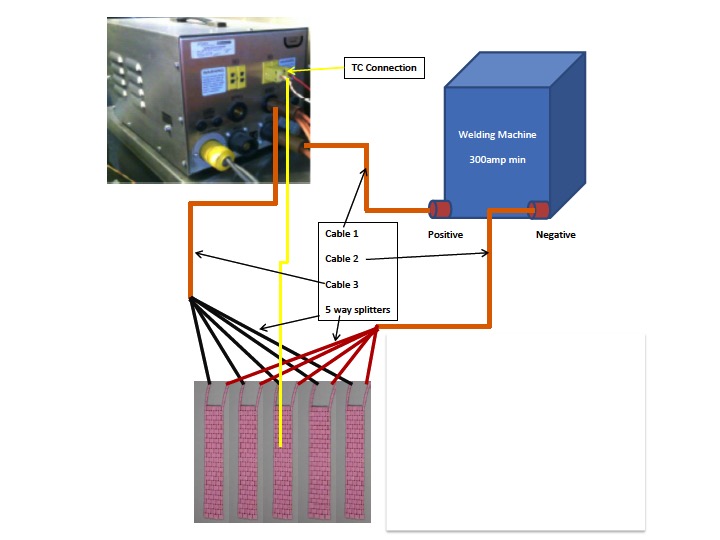

Twin Heat Module – Layout Diagram with Five Elements

Twin Heat Module – Replacement Parts List

| Components | Part Number |

| 300 Amp Panel Mounted Female Camlocks | 508-001 |

| 300A recessed Male Camlok | 508-003 |

| 110 V , 15 A Auxiliary Supply Socket P/M | 516-002 |

| Panel Mounted Thermocouple Socket | 516-125 |

| 250A contactor c/w Magnetic blow out | 526-050 |

| Panel Mounted Fuse Holders | 530-001 |

| 5 Amp 1.25″ Glass Fuse | 530-053 |

| 10 a 1.25″ Glass Fuse | 530-054 |

| Power on Neons | 538-017 |

| Temperature Controller | 548-055 |