Heater Beads

Flixible Ceramic Heater Pads

Resistance Heating

Heater Element Wire

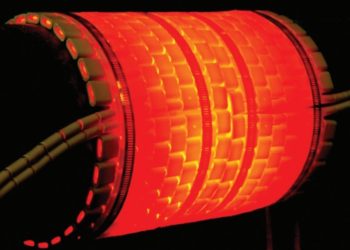

FLEXIBLE CERAMIC HEATING PADS – FCP

Available for shipping to USA & Canada

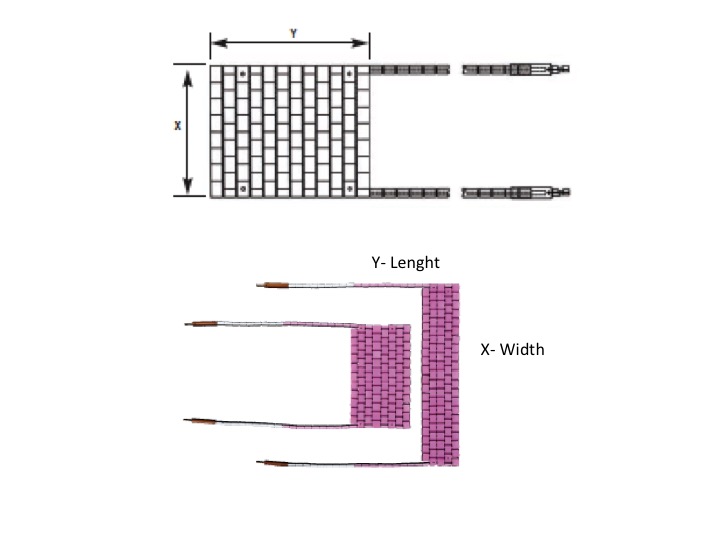

HOW TO MEASURE CERAMIC HEATING PADS SIZES.

FLEXIBLE CERAMIC HEATER – SIZES ( 60 /16 CORE WIRE )

Specification (60/16 Core Wire):

(All dimensions are nominal)

| Stock | Type | Width (tall to tall) | Length (of heater body) | Volts | Power | ||

| Reference | Reference | mm | inch | mm | inch | v | kw |

| 20230 | CP3 | 75 | 3.00 | 670 | 26.50 | 60 | 2.70 |

| 20231 | CP4 | 100 | 4.00 | 505 | 20.00 | 60 | 2.70 |

| 20232 | CP6 | 150 | 6.00 | 335 | 13.25 | 60 | 2.70 |

| 20233 | CP8 | 205 | 8.00 | 250 | 10.00 | 60 | 2.70 |

| 20234 | CP10 | 255 | 10.00 | 210 | 8.25 | 60 | 2.70 |

| 20235 | CP12 | 305 | 12.00 | 165 | 6.50 | 60 | 2.70 |

| 20236 | CP15 | 380 | 15.00 | 145 | 5.75 | 60 | 2.70 |

| 20237 | CP16 | 410 | 16.25 | 125 | 5.00 | 60 | 2.70 |

| 20238 | CP21 | 535 | 21.00 | 105 | 4.25 | 60 | 2.70 |

| 20239 | CP24 | 610 | 24.00 | 85 | 3.25 | 60 | 2.70 |

| 20240 | CP48 | 1220 | 48.00 | 45 | 1.75 | 60 | 2.70 |

| 21230 | CP3H | 75 | 3.00 | 925 | 36.50 | 80 | 3.60 |

| 21231 | CP4H | 100 | 4.00 | 690 | 27.25 | 80 | 3.60 |

| 21232 | CP6H | 150 | 6.00 | 465 | 18.25 | 80 | 3.60 |

| 21233 | CP8H | 205 | 8.00 | 360 | 14.25 | 80 | 3.60 |

| 21234 | CP10H | 255 | 10.00 | 295 | 11.50 | 80 | 3.60 |

| 21235 | CP12H | 305 | 12.00 | 230 | 9.00 | 80 | 3.60 |

| 21235 | CP15H | 380 | 15.00 | 190 | 7.50 | 80 | 3.60 |

| 21236 | CP17H | 430 | 17.00 | 165 | 6.50 | 80 | 3.60 |

| 21237 | CP21H | 535 | 21.00 | 145 | 5.75 | 80 | 3.60 |

| 21238 | CP39H | 835 | 33.00 | 85 | 5.25 | 80 | 3.60 |

| 21239 | CP40H | 1675 | 66.00 | 45 | 1.75 | 80 | 3.60 |

| 21240 | CP24H | 610 | 24.00 | 330 | 13.00 | 220 | 9.90 |

FLEXIBLE CERAMIC HEATER – SELECTION GUIDE

Heating Element Selection Guide:

(For heat treatment cycle up to 800C)

To be used as a guide only. Reference should always be made to specific code or specification heated width requirements.

| Nominal Bore | Pipe Wall Thickness Inches / (mm) | ||||||

| Inches | mm | 0-0.8 / (0-20) | 0.8-0.9 / (20-23) | 1.1-1.4 / (23-28) | 1.1 – 1.4 / (28-36) | 1.4 – 1.8 / (36 – 46) | 1.8 – 2.4 / (46-61) |

| 1.00 | 25 | 1 x CP48 | N/A | N/A | N/A | N/A | N/A |

| 2.00 | 51 | 1 x CP8 | N/A | N/A | N/A | N/A | N/A |

| 3.00 | 76 | 1 x CP12 | N/A | N/A | N/A | N/A | N/A |

| 4.00 | 102 | 1 x CP15 | N/A | N/A | N/A | N/A | N/A |

| 6.00 | 152 | 2 x CP12 | 2 x CP12 | N/A | N/A | N/A | N/A |

| 8.00 | 205 | 2 x CP15 | 2 x CP10 | 2000 | N/A | N/A | N/A |

| 10.00 | 254 | 3 x CP12 | 4 x CP8 | 2001 | N/A | N/A | N/A |

| 12.00 | 305 | 4 x CP10 | 4 x CP10 | 4 x CP10 | 2 x 4 x CP10 | N/A | N/A |

| 14.00 | 356 | 3 x CP15 | 4 x CP12 | 6 x CP8 | 6 x CP8 | 2 x 4 x CP12 | N/A |

| 16.00 | 406 | 2 x 4 x CP12 | 2 x 4 x CP12 | 2 x 4 x CP12 | 2 x 5 x CP10 | 2 x 5 x CP10 | N/A |

| 18.00 | 457 | 2 x 4 x CP15 | 2 x 4 x CP15 | 2 x 4 x CP15 | 2 x 5 x CP12 | 2 x 5 x CP12 | N/A |

| 20.00 | 508 | 2 x 5 x CP12 | 2 x 5 x CP12 | 2 x 5 x CP12 | 2 x 5 x CP12 | 2 x 6 x CP10 | 2 x 6 x CP10 |

| 22.00 | 559 | 7 x CP10 | 7 x CP10 | 8 x CP10 | N/A | N/A | N/A |

| 24.00 | 610 | 2 x 5 x CP15 | 2 x 5 x CP15 | 2 x 6 x CP12 | 2 x 6 x CP12 | 2 x 6 x CP12 | 2 x 7 x CP10 |

| 47.00 | 1194 | 2 x 12 x CP12 | 2 x 12 x CP12 | 2 x 12 x CP12 | 3 x 12 x CP12 | 3 x 12 x CP12 | 3 x 12 x CP12 |

| 63.00 | 1600 | 2 x 15 x CP12 | 2 x 15 x CP12 | 2 x 15 x CP12 | 2 x 15 x CP12 | 2 x 15 x CP12 | 3 x 15 x CP12 |

FLEXIBLE CERAMIC HEATER – SIZES ( 80 /20 CORE WIRE )

Specification (80/20 Core Wire):

(All dimensions are nominal)

3.60

| Stock | Type | Width (tall to tall) | Length (of heater body) | Volts | Power | ||

| Reference | Reference | mm | inch | mm | inch | v | kw |

| 20030 | CP3 | 75 | 3.00 | 670 | 26.50 | 60 | 2.70 |

| 20031 | CP4 | 100 | 4.00 | 505 | 19.50 | 60 | 2.70 |

| 20032 | CP6 | 150 | 6.00 | 335 | 13.00 | 60 | 2.70 |

| 20033 | CP8 | 205 | 8.00 | 250 | 9.75 | 60 | 2.70 |

| 20034 | CP10 | 255 | 10.00 | 210 | 8.00 | 60 | 2.70 |

| 20035 | CP12 | 305 | 12.00 | 165 | 6.50 | 60 | 2.70 |

| 20036 | CP15 | 380 | 15.00 | 145 | 5.75 | 60 | 2.70 |

| 20037 | CP16 | 410 | 16.25 | 125 | 5.00 | 60 | 2.70 |

| 20038 | CP21 | 535 | 20.50 | 105 | 4.00 | 60 | 2.70 |

| 20039 | CP24 | 610 | 23.50 | 85 | 3.25 | 60 | 2.70 |

| 20040 | CP10L | 250 | 10.00 | 85 | 3.25 | 30 | 1.35 |

| 20041 | CP48 | 1220 | 47.25 | 45 | 1.75 | 60 | 2.70 |

| 20042 | CP20L | 500 | 19.50 | 45 | 1.75 | 30 | 1.35 |

| 26260 | CT78 | 25 | 1.00 | 1950 | 77.00 | 60 | 2.70 |

| 26261 | CT36L | 25 | 1.00 | 915 | 36.00 | 30 | 1.35 |

| 21030 | CP3H | 75 | 3.00 | 925 | 35.50 | 80 | 3.60 |

| 21031 | CP4H | 100 | 4.00 | 690 | 27.00 | 80 | 3.60 |

| 21032 | CP6H | 150 | 6.00 | 465 | 18.25 | 80 | 3.60 |

| 21033 | CP8H | 205 | 8.00 | 360 | 14.25 | 80 | 3.60 |

| 21034 | CP10H | 255 | 10.00 | 295 | 11.25 | 80 | 3.60 |

| 21035 | CP12H | 305 | 12.00 | 230 | 9.00 | 80 | 3.60 |

| 21036 | CP15H | 380 | 15.00 | 190 | 7.50 | 80 | 3.60 |

| 21037 | CP17H | 420 | 16.00 | 165 | 6.50 | 80 | 3.60 |

| 21038 | CP21H | 535 | 21.00 | 145 | 5.75 | 80 | 3.60 |

| 21039 | CP33H | 840 | 33.00 | 85 | 3.25 | 80 | 3.60 |

| 21041 | CP66H | 1680 | 66.00 | 45 | 1.75 | 80 | 3.60 |

| 21042 | CP30H | 760 | 30.00 | 45 | 1.75 | 40 | 1.80 |

| 22005 | CP24H | 610 | 24.00 | 335 | 13.00 | 220 | 9.90 |

| 22006 | CP26H | 660 | 26.00 | 335 | 13.00 | 240 | 10.80 |

Construction:

Highest quality materials available in the construction of our Ceramic Pad (FCP) heating elements.

- Reduce work time

- Highly Durable

- Extended Life

- Reduce annual repair costs

Ceramic Beads

- High Resistance to Thermal and Physical Shock

- High grade sintered alumina ceramic beads 80/20 nickel cold tail wire.

- Flexibility and high heat transfer

Advantage:

- Reduce worktime

- Highest Quality materials

- Highly Durable

- Extended Life

- Reduce annual repair costs

Physical Properties:

- Alumina Content: 95 %

- Bulk Density Fired: 3.7 MG/M3

- Grain Size: 6 um

- Vickers Hardness: 12.5 ( GPA@Hv 0.5 kg )

- Rockwell Hardness: 78 (R45N)

- Compressive strength: 2000 Mpa

- Flexible strength: 320 MPA (ASTM C1161.3 point)

- Young Modulus: 325 Gpa

- Thermal Conductivity: 21 W/ m3

Heating elements are butt welded to the cold tails of ceramic eliminates the cold

heater core wire which eliminates the cold tail/core wire junction failures often

seen with low quality heaters which use steel ferrules.

Any pipe size or pipe configuration can be covered from the extensive range of

FCP heating elements, so that the correct amount of heating power can be

applied to successfully heat treat the pipe weld or other fabrication.

Flexible Ceramic pads heating elements are manufactured with a range of

power ratings for use with a selection of standard voltages.

If you require any special heating element configuration, voltage or power rating,

Viaduct Trading will use their heat treatment engineering expertise to provide you with a

heating element custom built to meet you exact needs.

If handled correctly, Stork FCP heating elements can be used approximately

fifty times at temperatures up to 1050ºC (1922ºF). Viaduct Trading Ltd can

provide higher temperature heating elements if required which can be used

repeatedly at temperatures up to 1200ºC